Types of Thermowell

Thermowells are cylindrical fittings that protect temperature sensors in industrial processes. A thermowell is a closed-end tube that is positioned in the process stream. A temperature sensor, such as a thermocouple, thermometer, or resistance temperature detector, is implanted in the open end of the tube, which is generally outside the process.

The thermowell wall is heated by the process fluid, which transfers heat to the temperature sensors. Because there is extra sensor-well assembly than a probe immersed directly into the process, the response of the sensor to changes in process temperature is decreased due to additional well material.

Thermowells are compatible with all Temperature Instrumentation and control systems, such as RTDs, Temperature Recorders, Thermometers, Thermocouples, and Temperature Controllers.

Types of Thermowell are:

- Connections

- U-Length

- Shank

- Lagging Extension

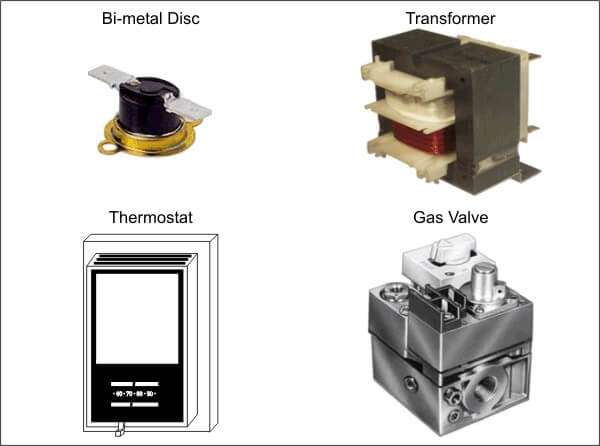

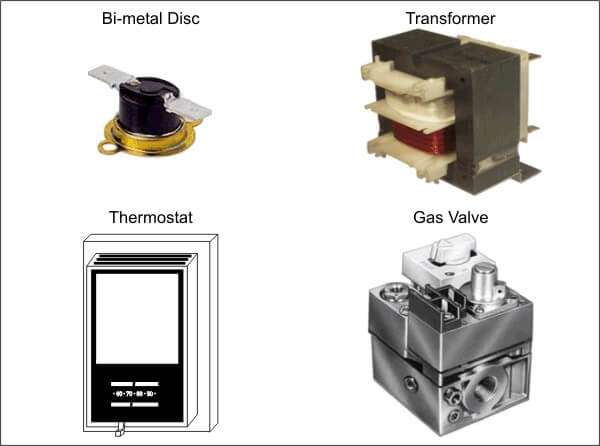

Types of Thermostats

There are several types of thermostats, each with a distinct working mechanism or the ability to be programmed. In a nutshell, mechanical and digital types exist, though, from a functional standpoint, there are only two categories: programmable and non-programmable. The smart type will also be discussed in greater detail at the conclusion of this article.

Types of Temperature Sensor

A temperature sensor is a machine that uses heat or temperature to operate. There are several types of temperature sensors. An electrical thermometer, for example, contains specific protection and a unit made up of one or more components, such as the neck tube, connection head, handgrip, and thermowell.

The temperature-sensing device is attached to the temperature sensor. The actual temperature is measured and converted into an electrical signal by the sensor component, which is fitted inside the temperature sensor. Several types of thermocouples and RTD (Resistance Temperature Detector) are used to sense temperature.

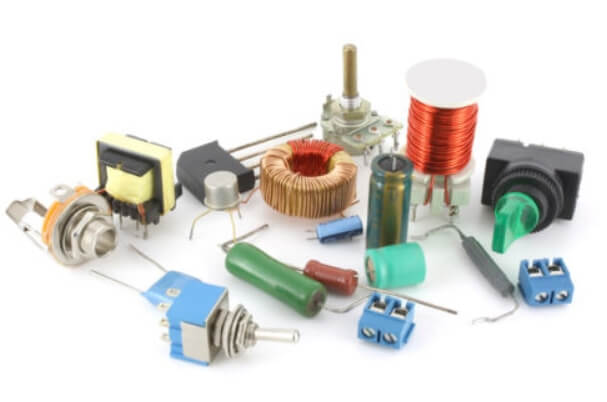

Types of Potentiometers

From the radio we listen to in the mornings to the television we watch at night, different types of potentiometers are used every day. These tiny yet useful components may be utilized for comparison, alteration, and other purposes. We'd like to discuss POT kinds and applications in this Linquip article. Continue reading to learn more about them.

A potentiometer (sometimes called a POT) is a three-terminal variable resistor. This resistor has an adjustable voltage, which you may manually vary to regulate the flow of electricity. It's all governed by Ohms Law. The potentiometer sign is made out of two linear lines with a rectangle or zigzag line between them.

Types of Potentiometers:

- Rotary Potentiometer

- Linear Potentiometer

- Digital Potentiometer

Types of Multimeters

There are a variety of multimeters available on the market, each with its own set of features. A multimeter is a crucial measurement tool that may be found in every engineering workshop and lab. The primary duty of this gadget is to measure the electrical characteristics of the equipment. It's also used in manufacturing for wiring duties.

Multimeters are being used for a variety of applications dependent on the demands, including electrical testers, laboratories, power sources & circuits. On the instrument's front side, you may pick various electrical parameters using a dial or a rotary knob.

There are two distinct types of multimeters: analog and digital. Digital multimeters may be classified into fluke, clamp, and auto-ranging. This article goes through these many sorts of multimeters in-depth, but first, let us look at what a multimeter is and how it may assist us without measurements.

Types of Humidity Sensors

Today, we'll take a look at the many types of Humidity Sensors. Humidity sensors, commonly known as hygrometers, are used to measure humidity levels in the air. Humidity sensors come in a variety of shapes and sizes.

A hygrometer or humidity sensor is an instrument that senses, measures, and reports both moisture and air temperature. Air humidity is a crucial consideration when designing an electronic device.

There are three distinct sorts of humidity sensors, each based on the method used to sense humidity and generate an electrical signal that may be utilized to compute the amount. These humidity sensor types are:

1. Capacitive humidity sensors

2. Resistive humidity sensors

3. Thermal conductivity humidity sensors

References:

- https://www.linquip.com/blog/types-of-thermowell-comprehensive-overview/

- https://www.linquip.com/blog/types-of-thermostats/

- https://www.britannica.com/technology/thermometer

- https://www.linquip.com/blog/types-of-temperature-sensor/

- https://www.britannica.com/technology/thermocouple

- https://www.linquip.com/blog/types-of-potentiometers/

- https://en.wikipedia.org/wiki/Measuring_instrument

- https://www.linquip.com/blog/types-of-multimeters/

- https://www.linquip.com/blog/types-of-humidity-sensors/